CARBON NEGATIVE - CLIMATE POSITIVE

BIOCHAR

THE MOST RAPID METHOD OF REVERSING CLIMATE CHANGE

WHY IS IT SO VALUABLE ?

CLIMATE CHANGE IS THREATENING FOOD AND FARMING SECURITY AROUND THE WORLD.

Biochar is proven to be one of the most effective ways of Sequestering carbon and considered the most rapid method of reversing climate change

When farmers use Biochar as a soil amendment or animal feed supplement, studies and years of “infield” use show they will benefit from:

- Bigger yields

- Bigger yields

- Stronger plants

- Less contamination

- Promotes seed germination

- Lower Carbon footprint

- Healthier soil

- Better water retention

- Richer soil life

- Higher fertility

- Healthier Animals

BIOCHAR USES

- Feed supplement to animals

- Building sector

- Odour Control

- Biogas Production

- Soil Amendment

- Wastewater treatment

- Textiles

- Decontamination of soils and water

- Addition to Construction materials – e.g. Concrete & Asphalt

- Drinking water treatment

- Wellness

HOW DO WE MAKE IT AND WHY?

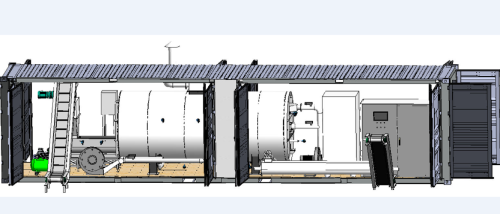

WE CONTINUOUSLY FEED THE PRE DRIED FEEDSTOCK (GRAPE MARC, PINE WASTES, HUSKS, FOGO ETC) INTO A PYROLYSIS MACHINE. THIS IS A SELF-FUELLED, SYNGAS RUN MACHINE THAT RADIATES HEAT TO A SEALED CHAMBER THAT HEATS THE FEEDSTOCK TO HIGH TEMPERATURES BETWEEN 350 AND 600C, IN AN OXYGEN STARVED ENVIRONMENT.

The high heat environment in the feedstock chamber, with little oxygen present, releases a gas from the feedstock called Syngas. This Syngas is harnessed to fuel the machine, hence self-fuelling.

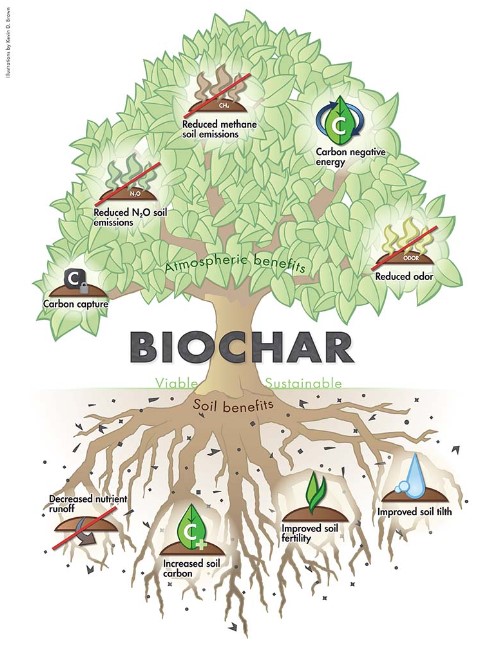

The Biochar and its carbon are then returned into the soil (carbon sequestering) where it stays for hundreds or thousands of years, storing water and nutrients to nourish soils and plant rootstocks as and when called on. All while providing a communication source between all the various soil structures.

Note: The publics’ general perception and understanding of Carbon is limited and generally that it is an atmospheric pollution and killer. However, Carbon in soil is hugely important. Studies show that for every 1 percent increase in soil carbon per hectare, results in an extra 130,000 litres of soil water holding and a 30pc increase in agricultural production. Carbon in the atmosphere originated from beneath the earth and when atmospheric carbon levels are too high, it has negative effects on earth health. The future sustainability of the earth demands us to sequester carbon back into soil where it has positive effects.

Different Biochars are made, based on different Pyrolysis temperature, length of exposure to temperature, feedstock, blends, minerals cooked with and process. These elements affect the quality, qualities, carbon levels and specific Biochar application.

There is also no “one size fits all” Biochar. Not all Biochars are the same as the quality depends on the feedstock and the skill of the operators.

The Pyrolysis process rapidly decomposes the feedstock into Biochar, Biochar has a very high surface area, resembling a honeycomb, that actually has a negative surface charge. By decomposing the cellulose hemicellulose and lignin, the carbon becomes stable within the Biochar and is not released into the atmosphere as CO2.

HOW BIOCHAR CAN HELP NEW ZEALAND AND THE EARTH?

BIOCHAR CAN ACT LIKE A MICROBIAL FUEL CELL POWERING THE PLANT TO TAKE UP NUTRIENTS MORE EFFICIENTLY AND INCREASE THE ABUNDANCE OF BENEFICIAL MICROBES THAT MAKE NUTRIENTS MORE AVAILABLE.

It can store and donate electrons to assist in chemical reactions that also make nutrients more available and reduce the bioavailability of some toxic compounds. It can do the hard work to find the minerals for the plant and make them readily available right beside the root structure, so the plant does not have to

go searching for the minerals

- Biochar helps plants take up nutrients by increasing the abundance of growth promoting micro-organisms and through reducing the energy required to transport nutrients from the soils to the inside of the roots.

- Biochar enhances the ability to make macro and micron nutrients more available to plants through facilitating chemical and microbial reactions on the external and internal surfaces of its pores

- Biochar adsorbs and binds root exudates, dead microbes, and other soluble organic matter in its pores. This builds up soil carbon and some of this carbon can be used as a source of energy for growth promoting microbes.

- It has a stable carbon content of greater than 50% that can last for hundreds and 1000s of years. This stable carbon sequestered into your soils can be sold on the voluntary carbon market.

- Biochar can reduce nutrient leaching and increase soil moisture. Each 1 percent increase in soil carbon per hectare can increase soil retention of water and nutrients by approximately 130,000 litres, to be released when called on by the plants. Therefore, less watering is required by the wine grower

- When small pieces of biochar are placed near the roots it can help plants resist disease and help regulate the uptake of specific nutrients

- If looked under a microscope, biochar has honeycombed like appearance. A piece of Biochar the size of the tip of your thumb (base of nail up) has the surface area of a basketball court.

- Not all Biochar is the same. Different applications require different recipes and cooking

- Biochar is best applied “preloaded” with nutrients or in a compost type environment – or it could initially compete for nutrients to “charge” itself

- Whilst we will test your soils and make recommendations of application – often less if more. Sometimes only .05% application annually can improve yield and quality of fruit, grains, grasses and vegetables

- New studies are proving that liquid Biochar applications applied at 200kg/ha can be effective in enhancing growth and quality as well as reducing cost of application.

- Biochar is known to reduce Methane production in animals and improve gut and digestive health, while increasing growth rates, milk production and improved hoof health.

HOW DO WE MAKE BIOCHAR AND WHY?

We continuously feed the pre dried feedstock (Grape marc, Pine wastes, husks, FOGO etc) into a Pyrolysis machine. This is a self-fuelled, syngas run machine that radiates heat to a sealed chamber that heats the feedstock to high temperatures between 350 and 600C, in an oxygen starved environment.

The high heat environment in the feedstock chamber, with little oxygen present, releases a gas from the feedstock called Syngas. This Syngas is harnessed to fuel the machine, hence self-fuelling.

The Pyrolysis process rapidly decomposes the feedstock into Biochar, Biochar has a very high surface area, resembling a honeycomb, that actually has a negative surface charge. By decomposing the cellulose hemicellulose and lignin, the carbon becomes stable within the Biochar and is not released into the atmosphere as CO2.

The Biochar and its carbon are then returned into the soil (carbon sequestering) where it stays for hundreds or thousands of years, storing water and nutrients to nourish soils and plant rootstocks as and when called on. All while providing a communication source between all the various soil structures.

Note: The publics’ general perception and understanding of Carbon is limited and generally that it is an atmospheric pollution and killer. However, Carbon in soil is hugely important. Studies show that for every 1 percent increase in soil carbon per hectare, results in an extra 130,000 litres of soil water holding and a 30pc increase in agricultural production. Carbon in the atmosphere originated from beneath the earth and when atmospheric carbon levels are too high, it has negative effects on earth health. The future sustainability of the earth demands us to sequester carbon back into soil where it has positive effects.

Different Biochars are made, based on different Pyrolysis temperature, length of exposure to temperature, feedstock, blends, minerals cooked with and process. These elements affect the quality, qualities, carbon levels and specific Biochar application.

There is also no “one size fits all” Biochar. Not all Biochars are the same as the quality depends on the feedstock and the skill of the operators.